Automotive manufacturers face a critical "digital divide" with their deskless workforce. Standard time clocks often leave shop floor employees disconnected from HR. By upgrading to AI-powered kiosks like CloudApper hrPad, companies can empower workers with self-service tools for schedules, PTO, and pay—keeping production lines moving and reducing administrative bottlenecks.

Table of Contents

In the automotive and manufacturing sectors, the gap between the corporate office and the shop floor is often digital. While HR teams and management operate on sophisticated cloud platforms like UKG, the “deskless” workforce—the assemblers, machine operators, and logistics staff who make up 80% of the company—are often left behind.

For many Original Equipment Manufacturers (OEMs) and Tier 1 suppliers, the physical time clock is the only digital touchpoint for these employees. If that clock is just a “dumb” punch-in device, you are missing a critical opportunity to streamline operations and engage your workforce.

Here is how forward-thinking manufacturers are transforming standard time clocks into AI-powered self-service hubs to solve the “deskless disconnect.”

TL;DR (Too Long; Didn’t Read):

-

The Problem: “Deskless” factory workers struggle to access HR info, causing downtime and admin overload.

-

The Solution: Replace “dumb” clocks with smart tablets (kiosks) using CloudApper hrPad.

-

Key Features: Instant access to accruals, timecard reviews, and shift scheduling right on the floor.

-

The Result: Improved operational efficiency, better compliance, and a more engaged workforce.

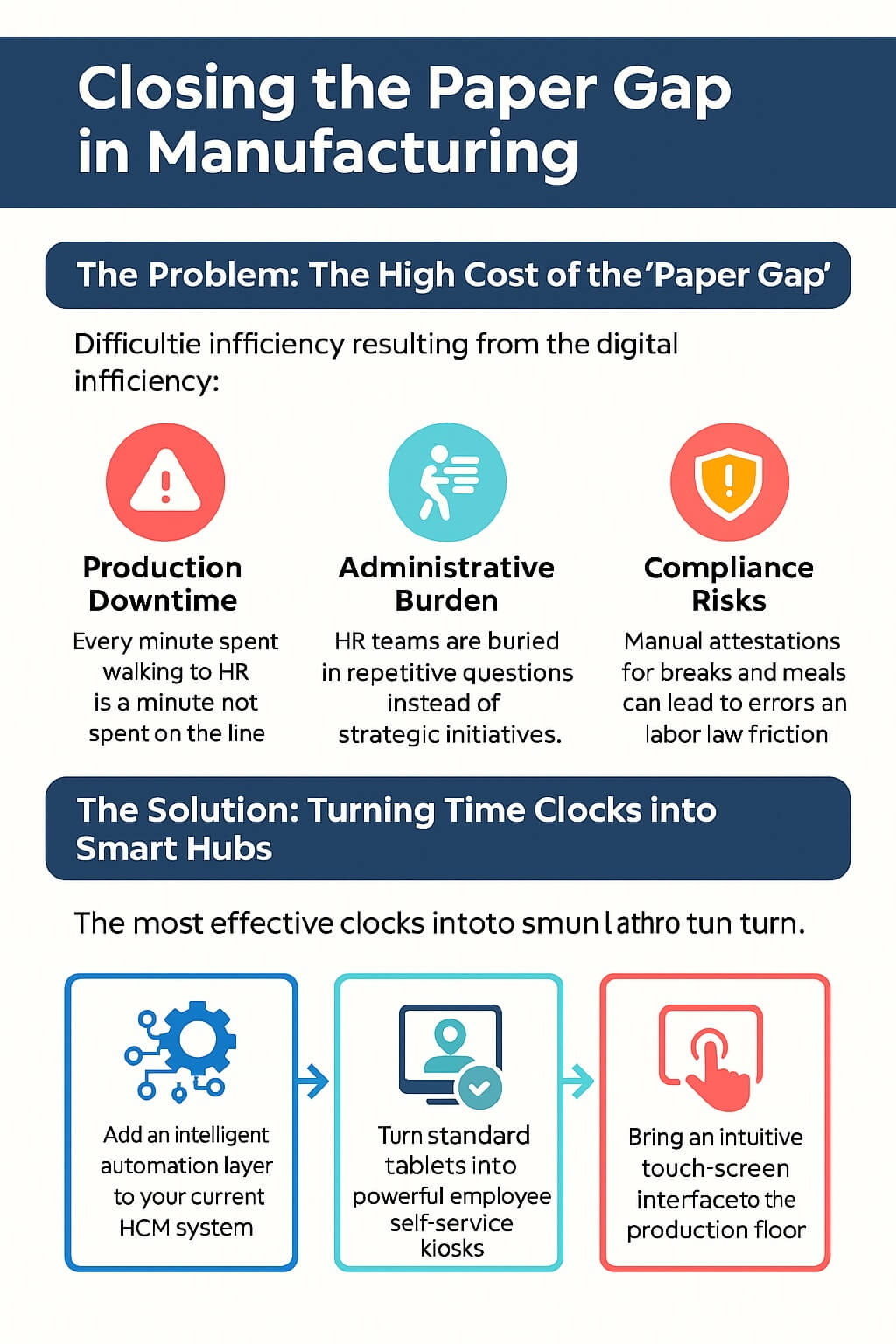

The Problem: The High Cost of the “Paper Gap”

In a high-speed manufacturing environment, efficiency is everything. Yet, many workforce management processes remain surprisingly manual for floor staff.

When an operator needs to check their PTO balance, review a schedule, or fix a missed punch, they often have to leave the line, walk to an HR office, or fill out a paper form. This creates a “Paper Gap” that results in:

-

Production Downtime: Every minute spent walking to HR is a minute not spent on the line.

-

Administrative Burden: HR teams are buried in repetitive questions (“How many vacation days do I have left?”) instead of strategic initiatives.

-

Compliance Risks: Manual attestations for breaks and meals can lead to errors and labor law friction.

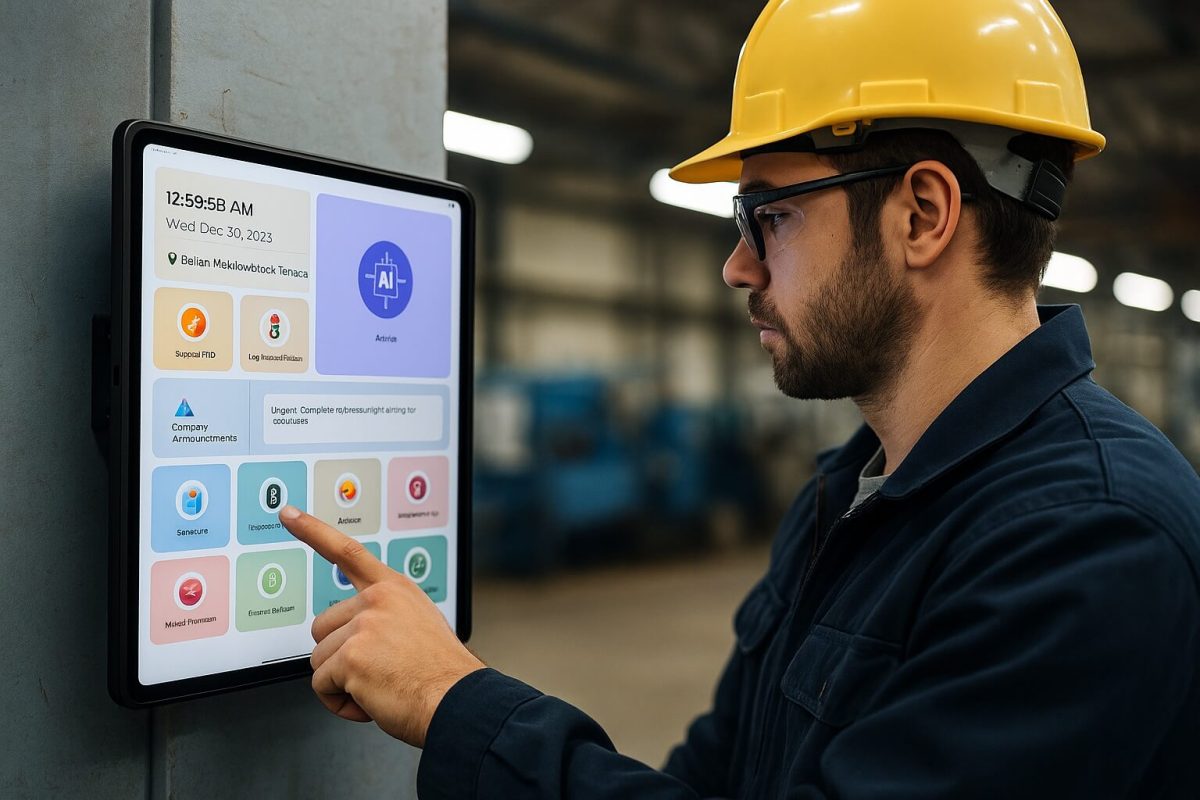

The Solution: Turning Time Clocks into Smart Hubs

The most effective solution isn’t to buy a new HCM system but to extend the value of your current one. By adding an intelligent automation layer—like CloudApper hrPad—to your existing UKG environment, you can turn standard tablets into powerful employee self-service kiosks.

This approach brings the full power of UKG directly to the production floor, accessible via a simple, touch-screen interface.

1. Empowering Employees with Real-Time Data

Instead of relying on a manager or a trip to the back office, employees can access their personal data instantly. Modern smart clocks allow staff to:

-

View real-time accrual balances (vacation, sick leave).

-

Check current and future schedules.

-

Review timecards for accuracy before the pay period closes.

This self-sufficiency boosts morale and drastically reduces the administrative traffic into the HR department.

2. Automating Shift Management and Time Off

In automotive manufacturing, shift coverage is critical. Smart kiosks can automate the complex logistics of scheduling. Employees can request Paid Time Off (PTO) directly from the clock. The system checks their accruals in real-time against the backend HCM and can even auto-approve requests based on pre-set rules.

Furthermore, these devices can capture punch-ins and punch-outs with precision, syncing instantly with the central system to ensure payroll accuracy without the lag time of manual data entry.

3. Seamless Communication on the Floor

One of the biggest challenges in a large facility is communicating with employees who don’t have corporate email addresses.

Smart time clocks solve this by acting as a digital bulletin board. Companies can push safety announcements, policy updates, or open enrollment reminders directly to the device. When an employee punches in, they see the message—ensuring 100% visibility for critical updates.

The Impact on Operations

By digitizing these “grunt work” processes, manufacturers see immediate operational improvements:

-

Reduced Unplanned Overtime: Better visibility into schedules and time-off requests helps managers plan shifts more effectively.

-

Higher Engagement: Employees feel valued when they have transparent access to their own data.

-

Streamlined Compliance: Custom attestations at the clock (e.g., “Did you take your full 30-minute break?”) provide a digital audit trail that protects the company.

Frequently Asked Questions (FAQ)

1. How can manufacturers improve workforce engagement with UKG?

Manufacturers can improve engagement by turning standard time clocks into self-service hubs. Using tools like CloudApper hrPad allows deskless workers to check PTO, view schedules, and receive company announcements directly on the production floor without needing a corporate email or visiting HR.

2. Can UKG time clocks handle employee self-service?

Yes, if you enhance them with the right software. While standard hardware clocks are limited, integrating an AI kiosk solution allows tablets to function as full self-service portals where employees can manage time-off requests, swap shifts, and review their timecards in real-time.

3. What are the benefits of smart kiosks for the automotive industry?

Smart kiosks reduce production downtime by allowing workers to handle HR tasks quickly during breaks or shift changes. They also improve compliance by enforcing break attestations and ensure that critical safety updates reach 100% of the workforce immediately.

4. Does CloudApper hrPad integrate with UKG Pro and UKG Ready?

Yes. CloudApper hrPad is designed to integrate seamlessly with both UKG Pro and UKG Ready. It syncs punch data, schedules, and accruals in real-time, ensuring that the backend system is always accurate without manual data entry.

For automotive suppliers and manufacturers, the workforce is the competitive advantage. Bridging the digital divide between the HR suite and the factory floor isn’t just about technology; it’s about empowerment and efficiency.

By upgrading to smart, AI-driven time collection devices, you can ensure that your UKG investment benefits every employee, from the front office to the final assembly line.

Ready to modernize your manufacturing workforce? Discover how CloudApper hrPad transforms standard tablets into powerful self-service kiosks for UKG.