In the multifaceted world of manufacturing, precise labor tracking is vital for maintaining efficient operations and financial transparency. This article addresses the importance of labor tracking and costs in manufacturing, reflecting on the procedures involved and introducing UKG AutoTime’s (previously Kronos Workforce AutoTime) capabilities in streamlining these vital operations.

Understanding Labor Tracking

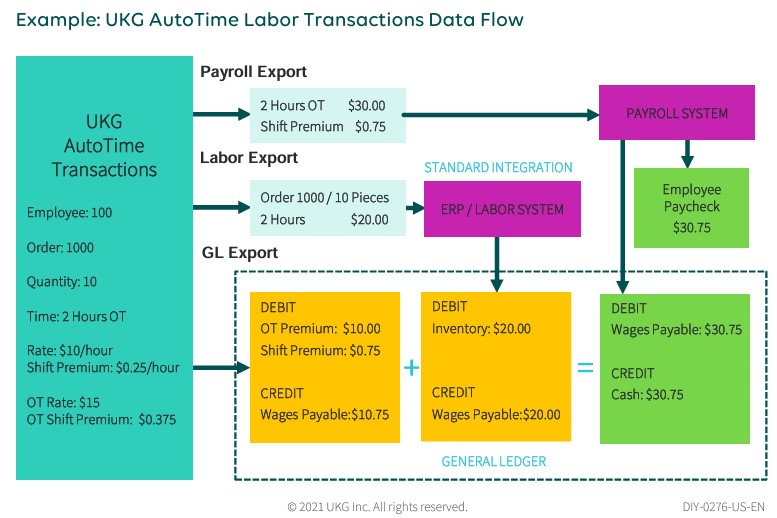

In the manufacturing space, labor tracking is the key to categorizing worked time across activities, projects, jobs, and work orders. Professionals and factory workers contribute to this data through various means, such as computer entry for engineering jobs or time clock scans for shop floor activity. Once captured, these labor transactions receive authorization, particularly for compliance with agencies such as the Defense Contract Audit Agency (DCAA). The interaction with enterprise resource planning (ERP) systems ensures real-time updates, allowing for better monitoring of work in progress (WIP) and expenses throughout the manufacturing process.

Understanding Labor Costing

While many businesses use labor standards to estimate product prices, this method falls short of reflecting the variation in employee compensation and work rates. True product costs are calculated by combining actual labor hours and an employee’s pay rate. UKG AutoTime steps in to offer tools for actual labor costing, enabling more accurate standard labor costing through real-time data data.

Importance of Labor Tracking and Costing

Efficient labor tracking and costing provide producers with critical data for measuring earned value, responding in almost real-time to budget variances, and optimizing both direct and nonproductive time. Additional benefits include accurate billing for government projects, DCAA compliance, and the availability of audit-ready data. UKG AutoTime is critical for effectively managing labor, guaranteeing compliance, and boosting overall business performance.

UKG AutoTime Labor Tracking Features

- Real-time validation of labor events, including charge filtration support.

- Comprehensive charge filtration capabilities to prevent cross-charging.

- Correct tracking of direct and indirect labor charges, with a complete audit trail.

- Total time accounting for equitable proration of employee rates across all projects.

- Flexible charge details capturing operation steps, activities, tasks, etc.

- Charges can be tracked simultaneously through batch or multiple job processing.

- Supervisor dashboard for optimized labor review processes.

- Overtime authorization and review are made easy.

- High precision tracking of transactions, down to hundredths of hours.

- Mandatory review and sign-off by both employees and managers for accuracy.

UKG AutoTime Labor Costing Features

- Application of different calculations for unique cost allocations.

- User-defined calculations using definable variables.

- Retroactive (prior period) calculations to facilitate retroactive payments.

- Control mechanism defining when calculations are executed.

- Support for productivity, utilization, and efficiency calculations.

In a constantly evolving manufacturing space, mastering labor tracking and costing is critical to success. With UKG AutoTime’s powerful capabilities, manufacturers can effortlessly handle the complexity of labor management, assuring efficiency, compliance, and precise financial information. Stay ahead of the manufacturing game by leveraging UKG AutoTime’s unrivaled control over labor tracking and costing.