Digitize your Pre-Shift Safety Checklists by integrating CloudApper AI TimeClock with UKG. Eliminate paper logs, ensure biometric identity verification, and centralize safety data to reduce workplace accidents and improve liability protection effectively.

Table of Contents

In high-risk environments, whether in manufacturing, logistics, or healthcare, a pre-shift safety checklist is the first line of defense against workplace accidents. It is the critical moment where an employee pauses to verify that their environment, equipment, and personal readiness meet safety standards.

However, many organizations still rely on clipboards and paper forms. This outdated method is often plagued by “pencil-whipping,” where checks are marked complete without actual inspection.

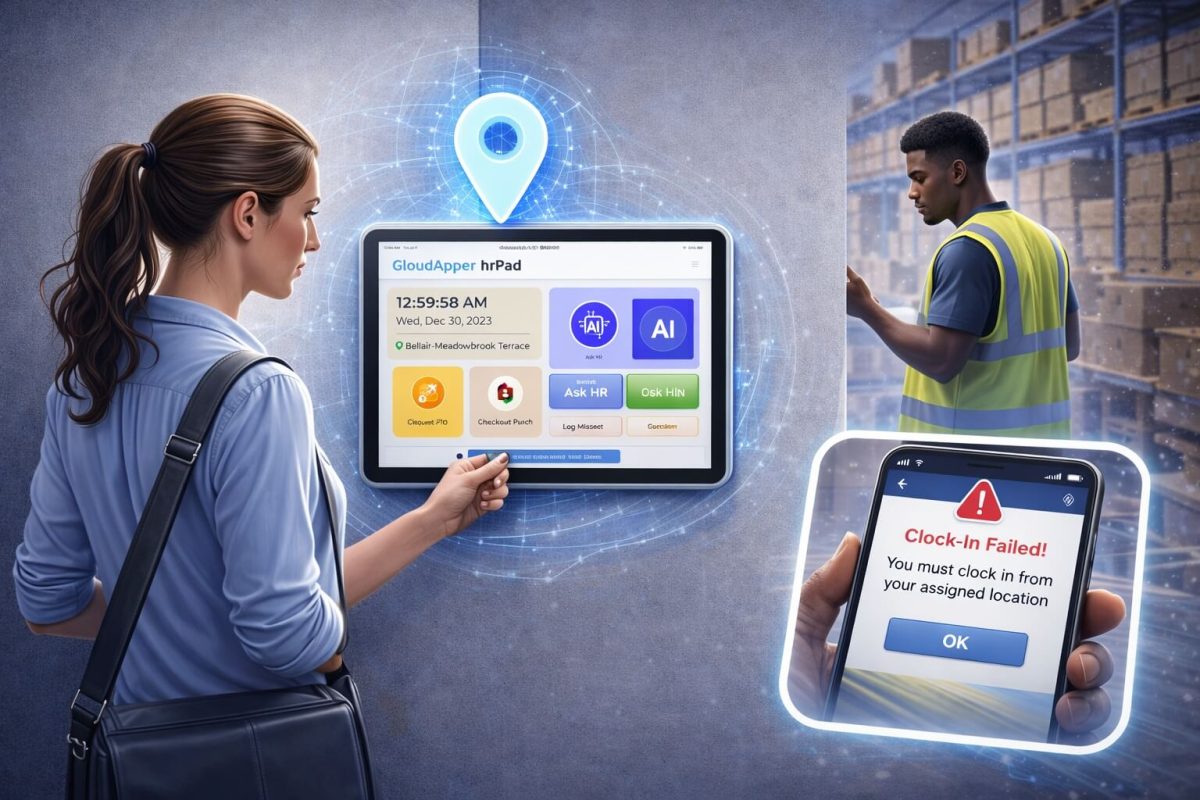

By integrating CloudApper AI TimeClock with your existing UKG ecosystem, you can digitize this entire process. CloudApper transforms your time clock into an intelligent safety kiosk, ensuring that no employee starts a shift without first verifying their safety status.

TL;DR:

-

The Issue: Paper-based Pre-Shift Safety Checklists are unreliable due to “pencil-whipping” (faking logs) and lost records.

-

The Solution: CloudApper AI TimeClock integrates with UKG to force a mandatory safety inspection before an employee can clock in.

-

The Workflow: Employees scan their face (biometric ID), answer custom Yes/No safety questions, and data syncs instantly to UKG.

-

The Result: 100% verified compliance, proactive hazard identification, and lower insurance liability.

What is a Pre-Shift Safety Checklist?

A pre-shift safety checklist is a critical risk management tool used in high-risk industries like manufacturing, construction, and healthcare. It is a mandatory series of inspections and attestations that an employee must perform immediately before starting their shift or operating equipment.

Unlike reactive safety measures (which address accidents after they happen), a pre-shift checklist is a proactive “gatekeeper.” Its primary purpose is to identify and isolate hazards—whether mechanical, environmental, or personal—before they have a chance to cause injury. It transforms safety from a theoretical policy into a daily, actionable habit.

A comprehensive pre-shift checklist generally covers three main pillars of workplace safety:

1. Personal Readiness & PPE Verification

This ensures the employee is physically protected and fit for duty.

-

Protective Gear: “Are you wearing the required high-visibility vest, steel-toed boots, and safety glasses?”

-

Fit-for-Duty: “Are you free from fatigue, illness, or medication side effects that could impair your ability to operate machinery?”

-

Training Validation: “Have you completed the required training refreshers for this specific workstation?”

2. Equipment & Machinery Integrity

This verifies that the tools of the trade are functioning correctly and safety mechanisms are active.

-

Safety Guards: “Are all machine guards and emergency stop buttons tested and functional?”

-

Mechanical Health: “Are fluid levels (hydraulic/oil) within safe operating ranges?”

-

Visual Inspection: “Are there any exposed wires, loose bolts, or visible damage to the equipment?”

3. Environmental Awareness

This assesses the immediate workspace for external hazards that could cause slips, trips, or falls.

-

Housekeeping: “Is the walkway clear of pallets, debris, and oil spills?”

-

Visibility: “Is the lighting in your work area functioning properly?”

-

Ventilation: “Are the ventilation fans running effectively in the chemical handling zone?”

By standardizing these questions, organizations ensure that safety is not left to memory or chance. Every shift begins with a confirmed baseline of safety.

The Hidden Costs of Paper Safety Checklists

While paper checklists are “better than nothing,” they rely entirely on the honor system. This creates three critical operational holes that undermine your safety goals:

- The “Pencil Whipping” Phenomenon:Without digital enforcement, supervisors have no way of knowing when a checklist was filled out. An employee might fill out a week’s worth of safety logs on Monday morning just to get it over with, leaving the organization vulnerable to accidents and liability.

- Lack of Identity Verification:On paper, a signature is easily forged. There is no undeniable proof that the certified operator was the one who inspected the machine, or if a colleague signed it for them.

- Data Silos and Lost History:Paper forms get damaged by grease, lost in shift changes, or piled into filing cabinets. If you need to find a specific safety report from six months ago for an audit, it is impossible to retrieve quickly.

| Feature | Paper Checklists | Digital Pre-Shift Safety Checks |

| Verification | Signature (Easily faked) | Face Scan (Biometric Certainty) |

| Timing | Often filled out retroactively | Real-time (Before shift start) |

| Data Access | Physical cabinets; vulnerable to damage | Secure Cloud; Instant Retrieval |

How the Pre-Shift Safety Checklist in CloudApper AI TimeClock Works

Integrating CloudApper with UKG doesn’t require complex new hardware; it works seamlessly with your existing setup to enforce safety protocols automatically. Here is the streamlined workflow:

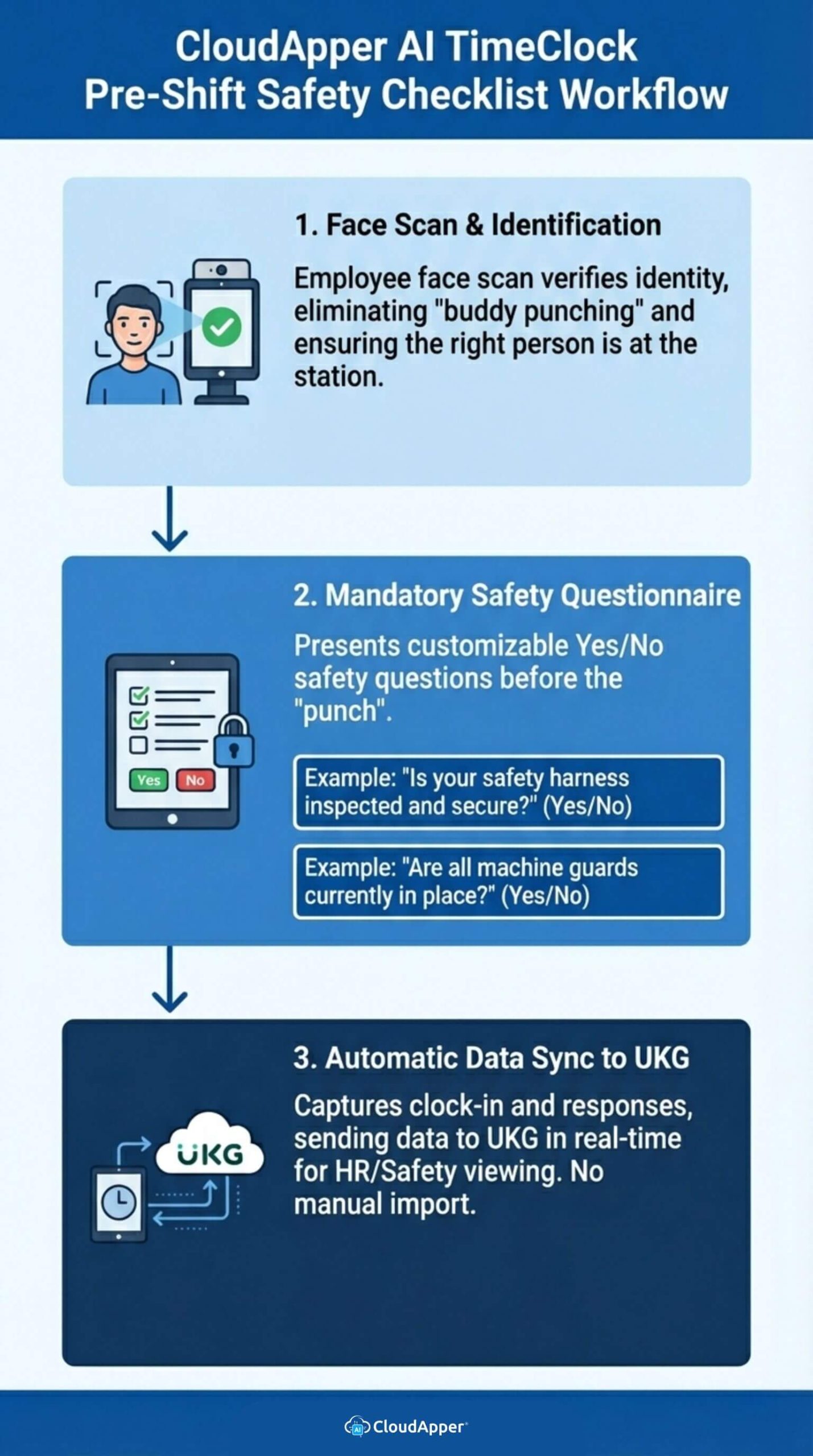

- Face Scan & Identification:The employee approaches the kiosk or tablet. The CloudApper AI TimeClock instantly scans their face to verify their identity. This eliminates “buddy punching” and ensures the right person is at the right station.

- Mandatory Safety Questionnaire:Before the shift creates a “punch” in the system, the AI TimeClock presents a series of customizable Yes/No safety questions.

-

Example: “Is your safety harness inspected and secure?” (Yes/No)

-

Example: “Are all machine guards currently in place?” (Yes/No)

-

- Automatic Data Sync to UKG:Once the employee answers the questions, the system captures both the clock-in time and the safety responses. This data is sent directly to UKG in real-time. There is no manual import required; your HR and Safety teams can view the attestation data directly within the ecosystem they already use.

Benefits of Using Digital Pre-Shift Safety Checklists in UKG

Switching to CloudApper AI TimeClock for UKG doesn’t just save paper; it fundamentally shifts your safety culture from reactive to proactive.

Proactive Hazard Identification

By forcing a pause for safety questions before the shift starts, you force a “mental reset” for the employee. They must actively look for hazards (like a spill or a missing guard) to answer the question truthfully. This catches potential accidents before machinery is turned on, drastically reducing workplace injuries.

Centralized Data for Better Decision Making

When safety data is trapped on paper, you cannot see trends. By digitizing responses into UKG, you can spot patterns. For example, if 40% of employees in Zone B are reporting “No” to “Is the floor dry?” on Tuesdays, management can investigate a potential leak or cleaning schedule issue before someone slips and falls.

Streamlined Internal Audits and Insurance

Insurance providers and internal auditors favor organizations with rigorous, documented safety protocols. CloudApper AI TimeClock for UKG provides an immutable digital audit trail. You can prove exactly who checked what and when. This level of transparency can often be leveraged to negotiate lower liability insurance premiums.

Enhanced Employee Accountability

When an employee scans their face and digitally taps “Yes, I am wearing my safety gear,” they are making a verified, personal commitment. This creates a stronger psychological bond to safety rules than casually signing a paper log that no one reads.

Conclusion

A pre-shift safety checklist is only effective if it is enforced and accurate. By moving from paper logs to CloudApper AI TimeClock, you ensure that safety is not an afterthought—it is the prerequisite for starting the day.

With seamless UKG integration, biometric verification, and real-time data syncing, CloudApper helps you protect your most valuable asset—your workforce—while modernizing your operations.

Are you ready to modernize your safety practices?

Contact us today to learn how CloudApper AI TimeClock can integrate custom pre-shift safety checklists into your UKG environment.