Manufacturers often struggle with rising time clock hardware costs and payroll risk. This article explains how one UKG user reduced time clock costs by 40% using a simple, trusted punch method that improved accuracy, adoption, and daily workforce operations.

Table of Contents

Every quarter, it starts the same way. Finance flags rising equipment spend. HR gets asked why time clock replacements keep showing up on the budget. Operations worries about punch accuracy during shift changes. You are under pressure to reduce time clock costs, but you cannot risk payroll errors or employee frustration. In manufacturing, one bad decision here creates problems across HR, payroll, and the floor.

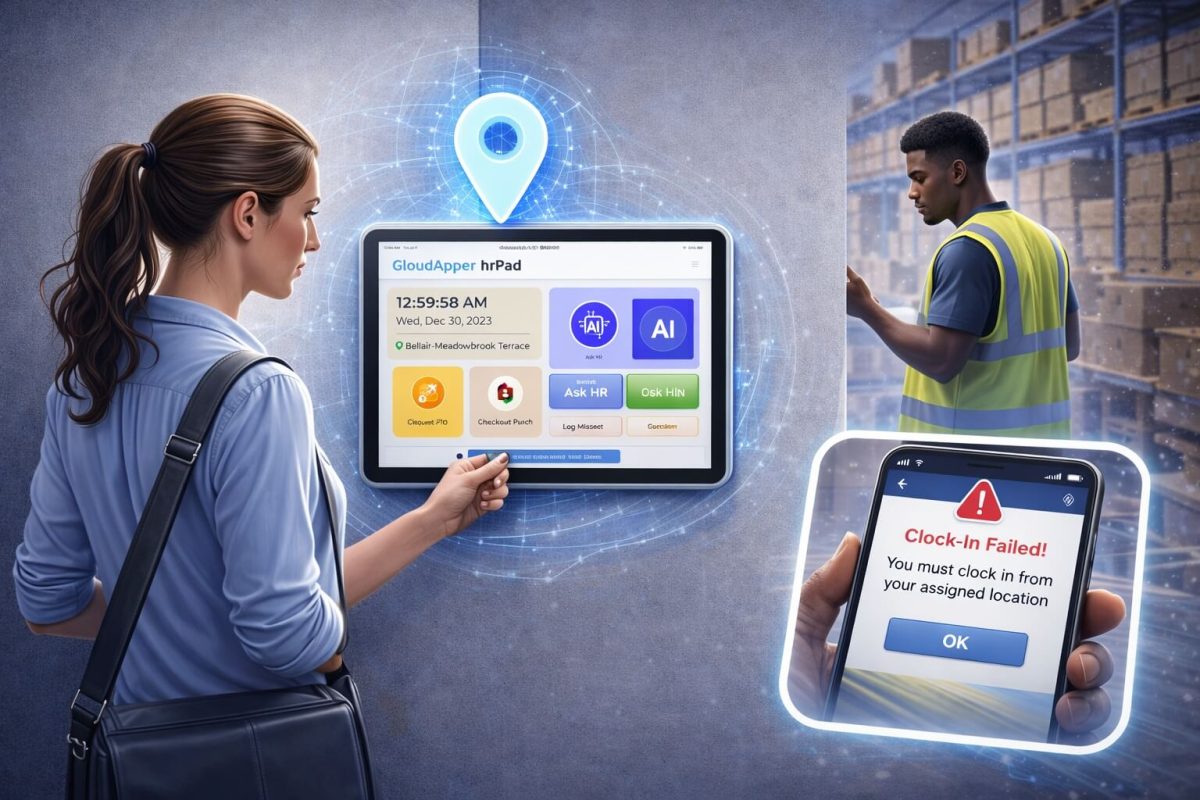

I have seen this exact situation play out with many UKG users using UKG Pro WFM (Dimensions). One manufacturer faced it head-on by rethinking how employees clock in instead of buying more hardware. They used CloudApper AI TimeClock for UKG to solve the cost problem without disrupting accuracy or trust. Their experience shows how a simple change can deliver real results. This is not just one company’s story. It’s a practical example of how manufacturers can reduce time clock costs using an approach that works across UKG environments.

TL;DR

-

You can reduce time clock costs by cutting unnecessary hardware and avoiding specialized devices that are expensive to maintain and replace.

-

PIN-based punch-ins work well in manufacturing because they are simple, fast, and easy for employees to use during shift changes.

-

Accuracy does not drop when punches sync directly into UKG Pro WFM (Dimensions), which reduces manual fixes and payroll errors.

-

Lower hardware dependence leads to fewer device failures, smoother shift changes, and less day-to-day HR and manager effort.

-

CloudApper AI TimeClock for UKG helps manufacturers balance cost control with reliable, trusted time tracking.

Why Manufacturing Time Tracking Gets Expensive So Fast

Manufacturing environments are tough on equipment. Shared devices run all day. Employees work across shifts. Dust, heat, and constant use shorten the life of hardware.

On top of that, companies often add more devices than necessary just to avoid long lines during shift changes. Each new device adds cost. There is the upfront purchase, setup time, ongoing maintenance, and eventual replacement.

Over time, time clock hardware costs quietly grow into a major line item. Most teams do not notice it until finance asks why costs keep climbing. If you are using UKG Pro WFM (Dimensions), you also feel extra pressure because time data touches everything. It affects schedules, attendance rules, and payroll readiness.

How Manufacturers Can Reduce Time Clock Costs Using a Simpler Punch Method

Let me zoom in on the part that mattered most for this manufacturer. They did not win because they picked a flashy method. They won because they chose a clock-in experience that employees accepted, managers could support, and HR could trust.

They landed on PIN-based punch-ins using CloudApper AI TimeClock for UKG Pro WFM (Dimensions). That choice did three things at once.

First, it helped them reduce time clock costs by cutting down the need for extra devices. Second, it kept punch data accurate because the punches synced straight into UKG. Third, it improved adoption because employees felt comfortable with the method.

In my experience, that combination is rare. Most companies only get one or two of those benefits at a time.

How PIN-based Punches Reduce Time Clock Costs in Manufacturing

PIN punches are not complicated. That is why they work.

Employees clock in using a shared tablet or kiosk already on site. They enter a secure PIN and complete the punch. You do not need a separate scanner. You do not need extra accessories. You do not need constant replacements because a dedicated device has failed again.

For this manufacturer, that meant fewer equipment purchases. It also meant fewer emergency replacements when something stopped working before a shift change.

Here is the part higher-ups cared about:

The company cut equipment costs by about 40% after moving to PIN verification. They did it by using what they already had and by reducing the number of devices they needed to keep running.

If you are sitting in HR or workforce management leadership, this is the kind of win you can explain in one sentence. We reduced hardware spending, and accuracy did not drop.

Why The Change Improved Accuracy, Not Just Cost

Some leaders hear “lower cost” and assume accuracy will suffer. In timekeeping, that concern is valid. One small issue can trigger payroll corrections, employee frustration, and hours of cleanup. In this case, accuracy improved for two clear reasons:

![]()

-

Consistent Experience: Employees followed the same simple punch process every day. There were no extra steps to remember and no dependency on managers to fix device issues. Simplicity reduced missed punches and exceptions.

-

Direct integration with UKG Pro WFM: CloudApper AI TimeClock synced punch data straight into UKG. HR and payroll teams avoided re-entry. Managers did not chase paper notes. Time data arrived on time and in the correct format.

-

Fewer manual touchpoints: When punch methods stay inside the UKG workflow, teams spend less time correcting data and more time reviewing it. The process became easier to explain, easier to audit, and easier to trust.

How The Implementation Looked on The Floor During Shift Changes

| Shift Change Challenge | What Was Happening Before | What Changed with PIN Punch-Ins |

|---|---|---|

| Employee congestion | Employees lined up at one or two central devices during shift changes | Tablets were placed where employees already walked, spreading traffic naturally |

| Device overload | High usage caused slowdowns and occasional failures at peak times | No single device became a bottleneck, reducing strain and downtime |

| Late or disputed punches | Delays led to late punches and “the line was long” explanations | Faster punch-ins reduced exceptions and attendance disputes |

| Workflow disruption | Employees waited to punch instead of moving directly to work areas | Employees punched quickly and continued moving without interruption |

| Attendance data confidence | Managers questioned accuracy during busy transitions | Cleaner punch data improved trust in attendance records |

If shift changes are where your time tracking breaks down, this is the point where small changes can make a big difference.

Employee Comfort and Trust Made the Rollout Smoother

This manufacturer also learned an important lesson that applies to almost every facility. You cannot force adoption with policy alone. People need to feel comfortable with how they clock in.

PIN-based punches were simple and familiar. Employees understood what was happening. They did not feel like they were being asked to use a method they did not trust. That improved cooperation and reduced resistance.

One HR leader told me something similar in another project. “If the method feels normal, the rollout feels normal.” That is a simple point, but it is very real.

When employees accept the process, your support load drops. When support load drops, your HR team gets time back.

Benefits that Showed Up After the Cost Savings

-

Fewer payroll corrections: Missed, duplicate, and disputed punches dropped because employees followed one clear and repeatable clock-in process every day.

-

Less time spent by managers: Managers no longer had to review exceptions, answer punch questions, or confirm hours during each pay cycle.

-

Reduced HR follow-up before payroll close: HR teams stopped chasing last-minute corrections, approvals, and explanations right before payroll deadlines.

-

Smoother shift changes on the floor: Employees punched in quickly and moved directly to work areas, which reduced crowding and delays at shift start.

-

More predictable daily operations: Time tracking became a routine background process instead of a daily issue that disrupted production and planning.

A Practical Checklist You Can Use Before Making a Change

If you are looking for a practical way to reduce time clock costs in your own environment, use this checklist before making any changes.

-

Count how many devices you currently maintain: Include kiosks, scanners, tablets, and any backup units across all locations.

-

Review device failure and downtime patterns: Note how often devices fail, slow down, or need support during peak shift changes.

-

Track replacement and repair costs over the last 12 months: Look at purchase history, emergency replacements, and maintenance expenses.

-

Identify where timekeeping problems happen most often: Focus on shift changes, overtime transitions, and high-traffic areas on the floor.

-

Assess employee comfort and adoption: Ask whether employees trust and easily use the current punch method without help.

-

Evaluate privacy expectations and compliance needs: Confirm whether the punch method aligns with employee expectations and company policies.

-

Question whether more hardware is truly the solution: Consider if adding devices fixes the root problem or simply increases long-term costs.

Final Thoughts

Manufacturers do not need to choose between accuracy and cost control. You can reduce time clock costs and still protect payroll quality if you pick a punch method that employees will actually use and you keep punch data connected to UKG.

This manufacturer found the balance by using CloudApper AI TimeClock for UKG Pro WFM (Dimensions) with PIN-based punch-ins. They cut equipment costs by about 40 percent, improved adoption, and reduced ongoing admin work.

If reducing time clock costs is on your roadmap this year, the next step is seeing what this could look like in your own environment.

Frequently Asked Questions

-

How can manufacturers reduce time clock costs without losing accuracy?

You can reduce time clock costs by cutting unnecessary hardware, using simpler punch methods employees will actually use, and keeping punch data synced directly into UKG Pro WFM (Dimensions). This helps lower equipment spend while protecting timecard accuracy.

-

Why do time clock hardware costs keep increasing in manufacturing?

Shared devices run all day, shift changes create heavy usage, and harsh floor conditions wear down equipment faster. Many companies also add extra devices to avoid lines, which increases purchase, setup, and replacement costs over time.

-

How does CloudApper AI TimeClock for UKG help reduce time clock costs?

CloudApper AI TimeClock for UKG supports punch options like PIN-based clock-ins that can reduce the need for specialized devices. It also syncs punch data into UKG Pro WFM (Dimensions), which helps reduce manual cleanup and payroll corrections.

-

Is a PIN-based time clock secure enough for manufacturing environments?

Yes. A PIN-based approach can be secure when you use unique employee PINs and follow your company’s access and policy controls. It also tends to be easy for employees to use, which helps reduce missed punches and disputes.

-

Will PIN-based punches work well during busy shift changes?

In many cases, yes. PIN punches are fast, simple, and can reduce bottlenecks because you can place shared tablets where employees already walk. This can help reduce lines, late punches, and shift-change disputes.