Manufacturers using UKG often struggle with time clocks that create privacy concerns, extra cost, and employee resistance. This article explains a real shift from biometrics to PIN codes and what truly matters when choosing a UKG-ready time clock solution today.

Table of Contents

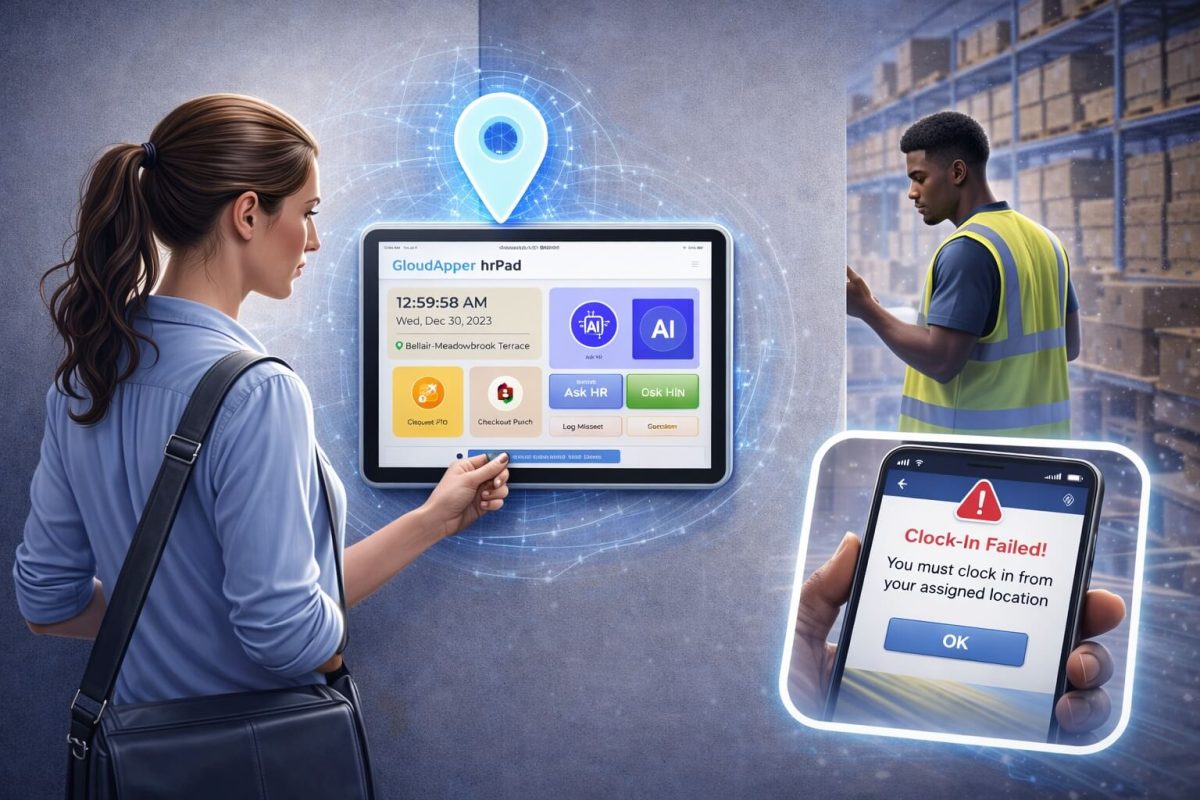

The moment a manufacturing employee asks, “Why do I need to scan my face to clock in?” you know the issue is no longer about accuracy or features, but about employee trust, comfort, and adoption. I have heard this question directly on shop floors, and once it comes up, time tracking stops being just an operational tool and becomes a workforce issue. Accuracy still matters, but privacy and ease of use matter just as much. When those factors are ignored, even a technically sound system can struggle on the floor. This is where a PIN code-based UKG/Kronos Time Clock for Manufacturing makes a real difference. And CloudApper AI TimeClock for UKG is the perfect tool for that.

It allows you to change how employees punch in and out without disrupting UKG workflows or payroll accuracy. In this article, I will walk you through a real manufacturing transition and explain what to look for in a UKG Kronos time clock for manufacturing that respects both operations and the people using it every day.

TL;DR

-

Manufacturing time clocks must balance accuracy with employee trust and ease of use.

-

Facial recognition can improve accuracy but often raises privacy and adoption concerns.

-

QR codes address privacy but introduce hidden operational and maintenance costs.

-

PIN code time clocks provide the best balance of privacy, cost efficiency, and usability.

-

A UKG/Kronos time clock for manufacturing must integrate cleanly and work reliably on the shop floor.

Why Time Clock Choices Matter in Manufacturing

n a manufacturing floor, time clocks quietly influence how smoothly every shift runs. When they work well, no one notices them. When they do not, the problems surface quickly across supervisors, payroll teams, and employees. Here is how time clock choices directly affect daily manufacturing operations.

-

High punch volume amplifies small issues

Manufacturing environments generate thousands of punches across multiple shifts. Even minor delays or errors at the clock multiply quickly, creating downstream issues that are difficult to contain once they spread. -

Supervisor time is pulled away from production

When time clocks are unreliable, supervisors spend valuable time fixing punches and answering questions instead of focusing on output, safety, and team coordination. -

Payroll accuracy depends on clean time data

Payroll teams often inherit problems that start at the time clock. Inconsistent or delayed punches lead to corrections, exceptions, and added pressure before payroll deadlines. -

Employee confidence is easy to lose and hard to rebuild

When employees question whether their time is being recorded correctly, trust erodes. Even small errors can lead to repeated disputes and manual workarounds. -

Compliance risk increases with inconsistency

Manufacturing often involves union rules, overtime thresholds, and local labor regulations. Inconsistent time data increases compliance exposure, even when policies are followed in good faith.

Choosing the right UKG/Kronos time clock for manufacturing helps stabilize these areas. When accuracy, usability, and integration work together, time tracking supports operations instead of creating friction.

The Initial Approach: Facial Recognition Time Tracking

Like many manufacturers looking to modernize, this company started with facial recognition using CloudApper AI TimeClock. The goal was clear. Improve accuracy, prevent buddy punching, and reduce manual corrections.

Where Facial Recognition Helped

From a system perspective, facial recognition delivered on accuracy. Each punch was tied to the right employee. Supervisors trusted the data. Payroll corrections dropped initially.

For leadership, this felt like progress. The technology worked as designed and aligned with broader modernization efforts.

Where Privacy and Adoption Became an Issue

The challenge did not come from the system. It came from the people using it.

Some employees were uncomfortable with facial scans. Others asked questions about how biometric data was stored and protected. Even with clear explanations, hesitation remained.

On a manufacturing floor, hesitation slows everything down. Employees delay clocking in. Supervisors field questions during shift changes. Over time, resistance builds.

This is where facial recognition often struggles in manufacturing. A solution can be secure and accurate, yet still fail if employees do not feel comfortable using it.

The Intermediate Solution: QR Codes for Employee Punch-In

To address privacy concerns without disrupting existing UKG processes, the company adjusted how they used CloudApper AI TimeClock for UKG. Facial recognition was replaced with QR code punch-ins, while the backend integration with UKG stayed exactly the same.

Each employee received a unique QR code to scan at the CloudApper-powered time clock. From a privacy standpoint, this change helped immediately. Employees no longer worried about biometric data. Adoption improved, and complaints dropped.

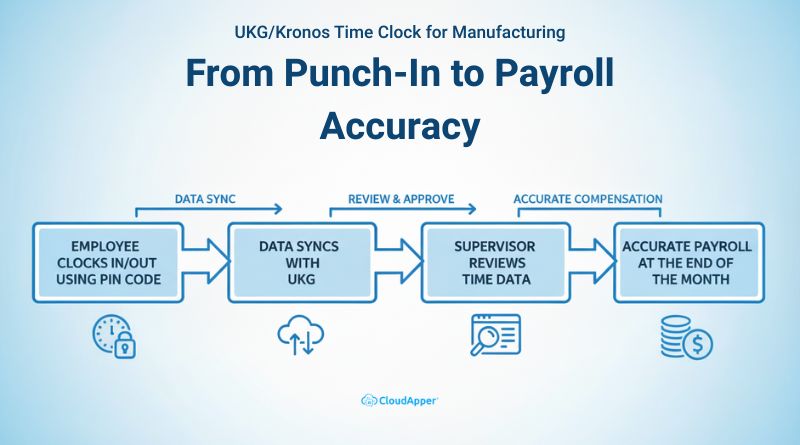

From an operational standpoint, the transition was smooth. Punch data continued syncing into UKG in real time. Supervisors reviewed timecards as usual. Payroll workflows remained unchanged. This flexibility is a key advantage of CloudApper AI TimeClock. You can change the punch method without disrupting the rest of your workforce management process.

Over time, though, practical challenges emerged. QR codes had to be printed and reissued. Scanners needed maintenance. Lost or damaged codes became a regular issue.

In a manufacturing environment with shift work and turnover, these small inefficiencies added up. The system worked, but it was not as cost-effective or simple as expected.

The Final Shift: PIN Code-based UKG/Kronos Time Clock for Manufacturing

After reviewing employee feedback, operational cost, and long-term usability, the company made one final change within CloudApper AI TimeClock for UKG. They enabled PIN code punch-ins. This decision focused less on novelty and more on what would work consistently on the manufacturing floor.

Why PIN Codes Aligned Better With Manufacturing Realities

Manufacturing environments demand speed and clarity. Employees often clock in while moving between tasks or shifts, not while standing still with time to troubleshoot issues. PIN codes matched that reality. Employees already understood how they worked, which reduced hesitation and errors from day one.

Because the process was familiar, adoption happened naturally. There was no need for extended training or policy explanations. The system fit into existing routines instead of forcing new behavior.

How PIN Codes Resolved Privacy Concerns Without Compromise

One of the biggest advantages of PIN codes was how clearly they addressed privacy concerns. No biometric data was captured. No personal identifiers beyond what UKG already managed were required. Employees immediately felt more comfortable using the system.

That comfort translated into consistent use. When employees trust the punch method, they stop questioning it and focus on their work. For supervisors, this meant fewer complaints and less time spent addressing concerns unrelated to production.

Operational Simplicity Reduced Daily Management Overhead

From an operational standpoint, PIN codes eliminated many small but persistent problems. There were no physical items to lose, replace, or reissue. There were no scanners to maintain or recalibrate. The time clock became one less thing managers had to worry about during busy shifts.

Supervisors reported fewer missed punches and exceptions. Payroll teams saw cleaner data flowing into UKG, which reduced manual corrections and follow-ups before payroll deadlines.

If managing time clocks still feels harder than it should on your manufacturing floor, it may be time to simplify the punch experience without disrupting UKG.

Maintaining Accuracy and Compliance With UKG Integration

Even with a simpler punch method, accuracy and compliance remained intact. CloudApper AI TimeClock continued sending real-time punch data directly into UKG. Validation rules, reporting, and approval workflows stayed the same.

This consistency mattered. The company did not have to retrain payroll teams or adjust compliance processes. The only change was how employees interacted with the clock, not how workforce management was handled behind the scenes.

Addressing PIN Sharing Concerns in Practice

Leadership initially raised concerns about PIN sharing. In practice, this risk was manageable. Clear policies, supervisor oversight, and UKG reporting made unusual patterns visible without creating friction for compliant employees.

More importantly, the overall reduction in errors and resistance outweighed the theoretical risk. Employees used the system correctly because it was easy and familiar, not because it felt restrictive.

Why This Matters for Manufacturing Workforce Management

Manufacturing workforce management depends on systems that employees trust and use correctly every day. When time clocks feel intrusive or difficult, small issues quickly turn into operational friction. Here is why these choices matter more than they often appear.

-

Employee trust directly affects data accuracy

When employees are comfortable with how they clock in, they are more likely to use the system correctly and consistently. This reduces missed punches, disputes, and the quiet skepticism that leads to manual workarounds. -

Time clock friction slows down shift transitions

Manufacturing floors run on tight schedules. Any delay at punch-in or punch-out creates bottlenecks, especially during shift changes. Simple punch methods keep lines moving and production on track. -

Payroll stability depends on clean upstream data

Payroll errors often start at the clock, not in payroll itself. Reliable punch data flowing into UKG reduces corrections, late adjustments, and last-minute exceptions before payroll closes. -

Privacy concerns can turn into operational resistance

Even when systems are technically secure, perceived privacy issues can lower adoption. Resistance shows up as hesitation, complaints, or inconsistent usage that managers have to resolve daily. -

Consistency matters more than advanced features

A time clock that works the same way every shift creates predictable behavior. That consistency supports compliance, simplifies training, and reduces the need for constant oversight.

A UKG/Kronos time clock for manufacturing should support these realities, not fight them. When privacy, usability, and integration are aligned, workforce management becomes more stable and easier to run.

Final Thoughts: Choosing What Actually Works

I have seen manufacturing teams adopt technology that looked impressive but failed on the floor. I have also seen simple changes dramatically improve daily operations.

This journey from facial recognition to QR codes to PIN codes was not about stepping backward. It was about listening to employees and choosing what fit the environment.

If you are evaluating your UKG/Kronos time clock for manufacturing, focus on privacy, cost, and usability together. When those align, everything downstream becomes easier.

If your goal is to reduce friction, protect employee trust, and keep UKG workforce management running smoothly, the right time clock choice can make all the difference.

Frequently Asked Questions About Manufacturing Time Clocks

-

What is the best time clock for manufacturing?

The best time clock fits your environment, respects employee privacy, and integrates cleanly with UKG. For many manufacturers, PIN-based systems offer the right balance of simplicity and reliability.

-

Are biometric time clocks legal in manufacturing?

Biometric time clocks may be legal depending on local regulations, but privacy laws vary. Even when allowed, employee acceptance should be considered carefully.

-

Is facial recognition safe for employees?

Facial recognition can be technically secure, but safety also includes privacy perception. If employees are uncomfortable, adoption and trust can suffer.

-

Can PIN code time clocks be secure?

Yes. With clear policies and UKG reporting controls, PIN code systems remain reliable and widely accepted on manufacturing floors.

-

Does CloudApper AI TimeClock integrate with UKG Kronos?

Yes. CloudApper AI TimeClock integrates with UKG Kronos to ensure accurate, real-time punch data and smooth workforce management processes.